Panabrid Metal foil composite film

- TOP

- Products and service

- Features of Products

- Panabrid Metal foil composite film

Panabrid

Metal foil composite film

- No occurrence of voids bubbles between the interlayer.

- Stacked without any curl even the materials are in different coefficient of linear expansion.

- Adhesive with high adhesion, high transparency with chemical and heat resistance.

- The finish good will be in flat form and without any carl.

Processing Overview

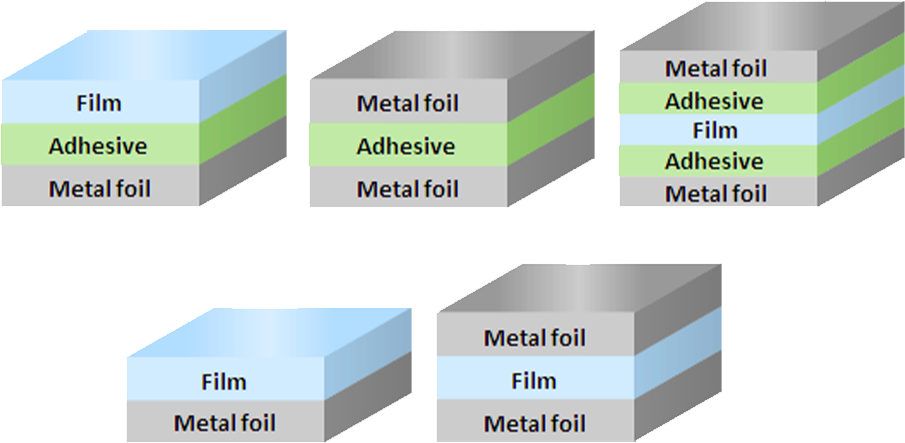

The metal foil and the plastic film is bonded by adhesive(dry lamination) or by heat melting(thermal lamination). Laminate is also possible for three or more layers upon request.

Composite configuration example COMPOSITION

| Actual use of metal foil |

|---|

| SUS:10~100μm AL:9~200μm Cu:12~70μm Other:Fe,Ti,etc.. |

| Actual use of film |

|---|

| PET,PEN,PI,PTFE,etc.. Thickness correspondence:4~500μm |

| Adhesive | |

|---|---|

| Elastic modulus control | Follow-up / curl control to the substrate expansion and contraction |

| Chemical resistance | Etch resistance |

| Adhesive force control | Ensure the adhesive force between the various metal foil / plastic film |

| Functionality grant | Rust function / antistatic |

Product Examples PRODUCT EXAMPLES

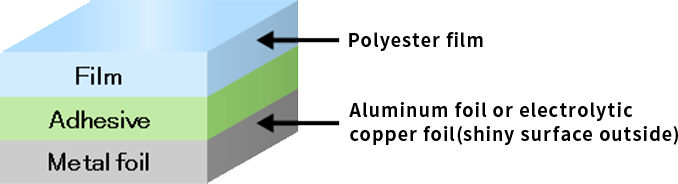

Al-PET, Cu/PET

Bonding product of aluminum foil or electrolytic copper foil with polyester film by adhesive in-between.

Have been used in the field required such as electromagnetic shielding by its electrical characteristics.

| Al-PET | Cu/PET | ||||

|---|---|---|---|---|---|

| Part number | 12-50 | 20-75 | 30-12 | 18-25 | 35-50 |

| Metal foil | Aluminum foil | Electrolytic copper foil | |||

| Metal foil thickness(μm) | 12 | 20 | 30 | 18 | 35 |

| Adhesive layer thickness(μm) | 2~3 | 20 | |||

| PET film thickness(μm) | 50 | 75 | 12 | 25 | 50 |