現在のページはHOME![]() About Us

About Us![]() The Four Functions of PANAC

The Four Functions of PANAC![]() Conversionのページです。

Conversionのページです。

Conversion

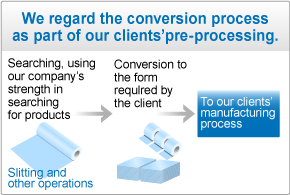

We convert the film to the optimum form

At PANAC, we convert films to various forms that meet the requirements, instead of simply delivering the film in rolls. We strive to enhance our clients' ease of using the film.

A processing system that responds to detailed orders

We aim to deliver films in a convenient form for our clients. We are more than happy to accept small-lot orders. Our state-of-the-art processing system responds to varied, small-lot production.

Processing variations

- Coating (Adhesives, laminates, AS, various coatings)

- Slitting (Multi-purpose slitting, micro-slitting)

- Sheet cutting

- Laminate slitting

- Laminate cutting

- Cut-outs (Thompson:full cut-outs, half-cuts)

- Annealing

- Ultrsonic bonding

- Cutting

- Chip processing (punching holes)

- Inspection of appearance and physical properties

Examples of processing machines

| Coating department | Conversion department |

|---|---|

|

|

A large number of processing variations and superior technology

At PANAC, we offer a variety of processes, from slitting and cutting to cut-outs, bending, adhesive processing, or matting, laminating and coating. We develop equipment in-house to enable special processing.

Technological characteristics

- Coating design technology

- Formulations (Polymers, additives, fillers, ultra violet ray absorbent, oxdization inhibitors, etc.)

- Compound technology (synthesizing and compounding special polymers)

- Coating technology

- We have multiple types of coater heads, allowing appropriate coating of coats having various degrees of adhesion.

- Conversion technology

- Slitting (multi-purpose, micro-slitting)

- Sheet cutting

- Laminate slitting

- Cut-outs (entire cut-outs, half-cuts)

- Annealing

- Supersonic wave bonding

- Capable of processing that combines the above

- Chip cutting (cut-outs using molds) and punching

- Inspection technology

- Automatic surface form inspection machine (reflections, transparency)

- Capable of quality inspections on optical films

- Analysis and measurement technology

- Thermal analysis

- Spectral analysis (UV, visible, IR)

- Energy dispersive x-ray electrometer (EDX)

- Adhesion measurement

- Various acceleration tests (light resistance, heat/temperature, cooling, heating)

- Measurement of roughness using laser microscopes

Achieves high-quality processing using clean rooms

Processing demands strict quality. That is why we have installed a clean room and subject the processes to strict management. Coating is classified as a clean room process, and we achieve consistency in our high-quality processing.