Punching

Punching

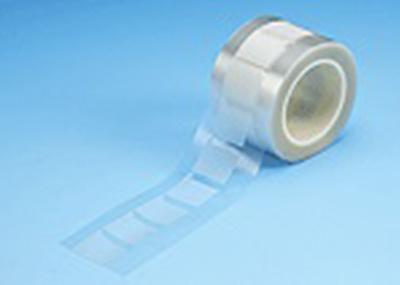

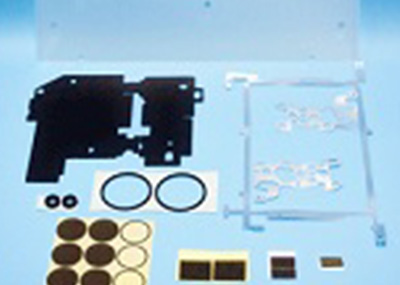

We offer punching process to the size requested by our various processing methods according to customer's application. All processing is done in a clean room.

We can process film materials into all sorts of shapes and sizes.

Feature FEATURE

-

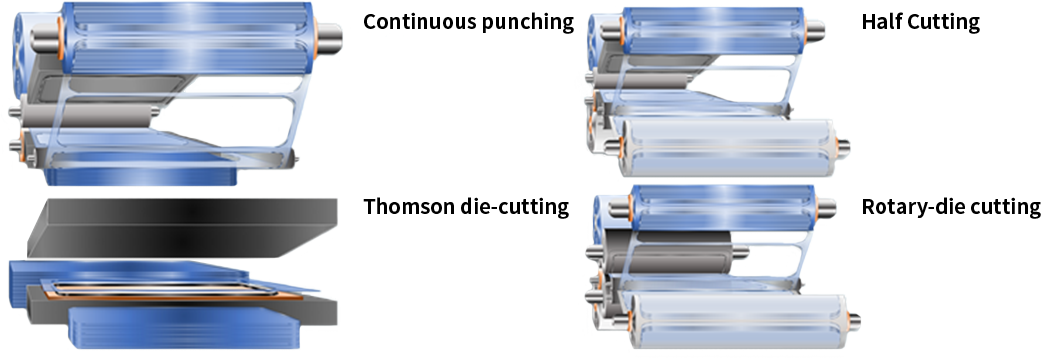

Various punching processing, such as automatic continuous punching, rotary die cutting, Thomson punching etc. are possible at our factory.

-

The mold to be used is designed by our company.

-

We have various inspection facilities and systems to realize high quality.

Idea Idea is here!

-

Thomson punching supports large size sheets (at subcontractor).

-

Roll Thomson punching can automatically remove unnecessary parts at the time of punching.

-

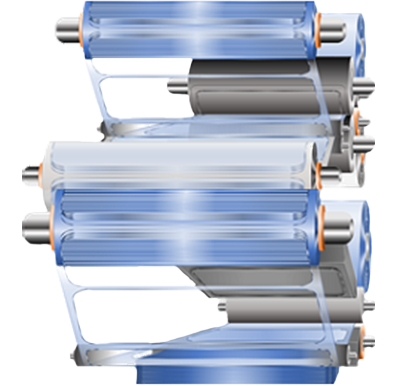

The rotary die cutter can kiss-cut while laminating protect film on the film, and it is possible to wind up the carrier (product) to the core. The rotary die cutter is suitable for mass production because the drawing die rotates.

-

Other processing methods such as laminate cutting can be combined.

Processing Details PROCESSING DETAILS

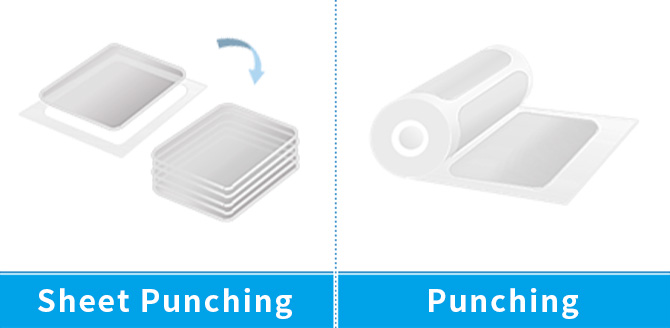

Roll to Sheet Punching machines

| Corresponding size | Material roll width | Blade type |

|---|---|---|

| Input side | 500㎜×Φ660㎜ MAX(IN) | Thomson blade Etching blade ( Pinnacle ) Carving blade |

| Outlet side | 480㎜×520㎜ MAX(OUT) (The minimum width:4mm) |

| Material | Plastic film/Foam/Metal foil/Double-sided tape Such as those of the composite industrial material |

| Material thickness | 3 |

Sheet to Sheet Punching machines

| Corresponding size | Material roll width | Blade type |

|---|---|---|

| Input side | 1550×1650㎜ MAX(IN) | Thomson blade (Main) |

| Outlet side | 1100×1550㎜ MAX(OUT) |

| Material | Plastic film/Foam/Metal foil/Double-sided tape Such as those of the composite industrial material |

| Material thickness | 2 |

※Processing specifications are only guidelines, please contact us for more information.

※Illustrations are only schematic diagrams. They are different from the actual.