Other (Laser cutting and Knurling)

- TOP

- Products and service

- Processing and services

- Other (Laser cutting and Knurling)

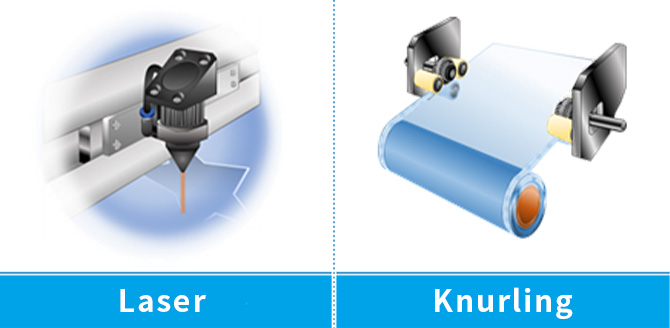

Laser Cutting

Knurling

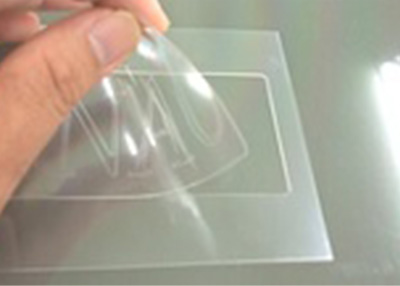

It is possible to cut a thick plastic sheet such as an acrylic plate into a free shape by carbon dioxide gas laser cutter.

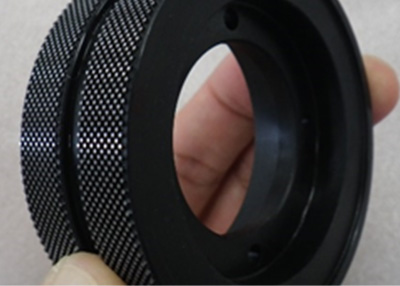

By knurling processing, unevenness is formed on both edge faces of the film in order to prevent surface deterioration due to blocking during winding of an optical film or the like.

We can process film materials into all sorts of shapes and sizes.

Feature FEATURE

-

In order to respond to customer's request, we will work on new processing technology.

-

All processing is done in clean rooms.(Class10000 or Class1000)

-

It is posible to respond to customer's request from large lot to small lot with flexible production system.

-

We can deliver high quality products through in-house production,One Stop Solution.

Laser cutting specifications

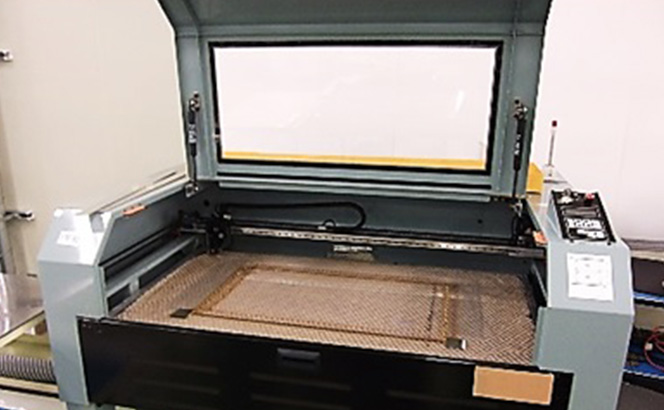

Processing machine introduction PROCESSING MACHINE

Laser cutter is suitable for punching of free form, trial manufacture and small lot processing.

We can also propose a processing method corresponding to mass production quantity timely.

Unlike the cutting plotter, the laser cutter does not cut with making any particles, so the cut is finished cleanly.

| Laser type | Spot diameter | Processing size |

|---|---|---|

| Carbon dioxide laser | Φ0.2㎜ | 950×550㎜ below |

| Notices |

|

※Processing specifications are only guidelines, please contact us for more information.

Processed products sample SAMPLE

Knurling processing specification

Processing machine introduction PROCESSING MACHINE

Knurling processing is a kind of processing uses metal mold to change surface shape at both ends of plastic film.

By this processing can prevent film loosing, as well the scratches due to friction.

| Corresponding size | Roll width | Processing height |

|---|---|---|

| Material input | 200〜1,350mm | 1〜10μm degree |

| Available material | PET, TAC, PC, etc. |

※Processing specifications are only guidelines, please contact us for more information.