Slitting and Lamination slit

- TOP

- Products and service

- Processing and services

- Slitting and Lamination slit

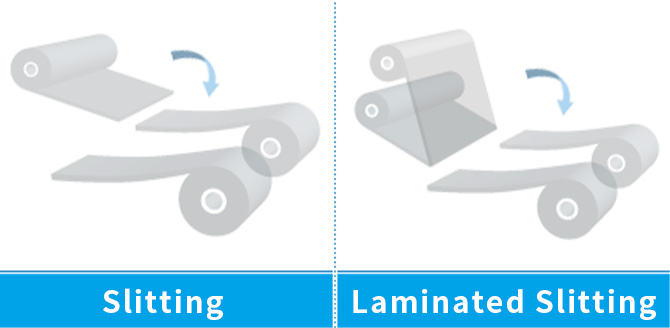

Slitting and

Laminated Slitting

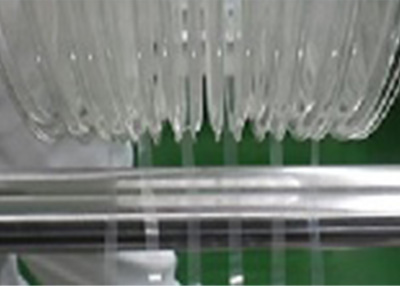

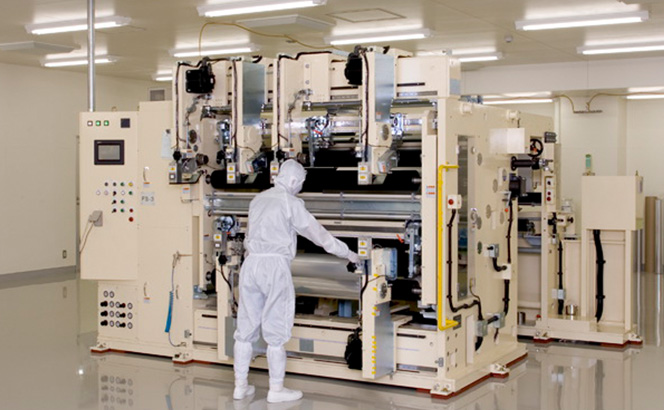

We can slit a various kinds of materials such as plastic film, optical film or metal foil to a specified size in our clean room. Cutting into sheets from roll is also available. And we can laminate(roll to roll /sheet to sheet) different material on both sides of products.

Finally, we can deliver product at your ordered quantity.

We can process film materials into all sorts of shapes and sizes.

Feature FEATURE

-

All processing is in clean rooms.(Class 10,000 or 1,000)

-

We have a production system from large lot to small lot.

-

We can laminate up to 3 layers, slit materials and cut materials at the same time.

Idea Idea is here!

-

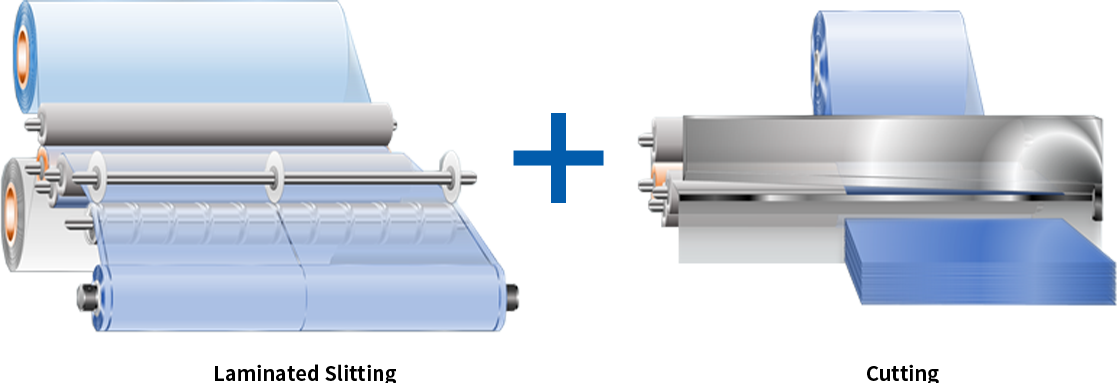

Laminating + slitting + cutting can be selected

-

Laminating + slitting + cutting processes can be selected

-

Proposing various other processing methods as necessary

Processing Details PROCESSING DETAILS

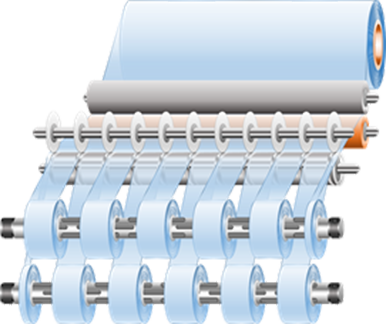

Standard Slitting

| Available size | Material roll width | Material weight | Maximum winding diameter |

|---|---|---|---|

| Input side (Unwinding side) | ~1350㎜(1600㎜) | ~800kg | ~Φ500㎜(Φ700㎜) |

| Outlet side (Rewinding side) | 60~1600㎜ | ~200kg(300kg) | ~Φ500㎜(Φ700㎜) |

| Material thickness | 6~350μm |

| Number of machines | 7 |

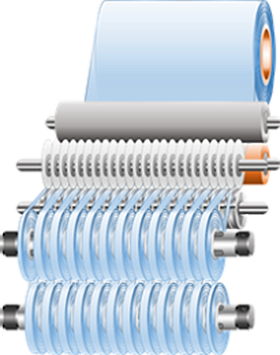

Micro Slitting

| Available size | Material roll width | Material weight | Maximum winding |

|---|---|---|---|

| Input side (Unwinding side) | ~650㎜(750㎜) | ~100kg(300kg) | ~Φ500㎜(Φ800㎜) |

| Outlet side (Rewinding side) | 6~630㎜ | ~60kg(90kg) | ~Φ350㎜(Φ550㎜) |

| Material thickness | 4~500μm |

| Number of machines | 4 |

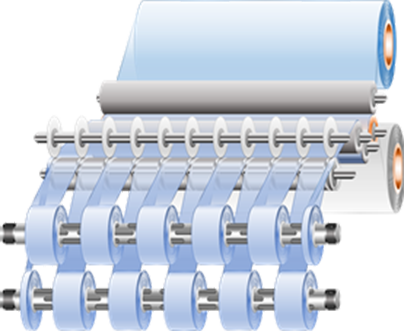

Laminated Slitting

| Available size | Material roll width | Material weight | Maximum winding diameter |

|---|---|---|---|

| First feed | ~1700㎜ | ~850kg | ~Φ800㎜ |

| Second feed | ~1700㎜ | ~850kg | ~Φ700㎜ |

| Outlet side (Rewinding side) | 100~1700㎜ | ~300kg/軸 | ~Φ600㎜ |

| Material thickness | 12~350μm |

| Number of machines | 12 |

※Processing specifications are only guidelines, please contact us for more information.

Processing machine introduction PROCESSING MACHINE

Processed product samples SAMPLE

Processing performance (partial) CASE

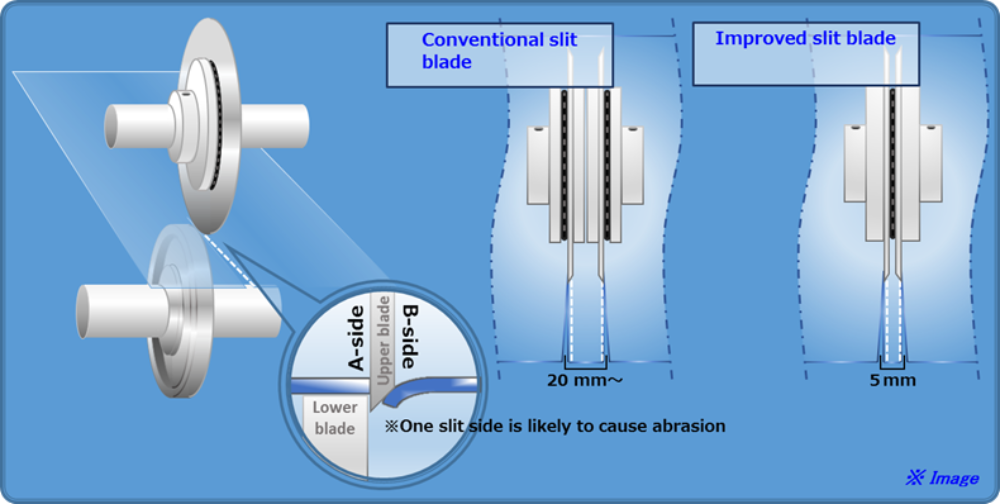

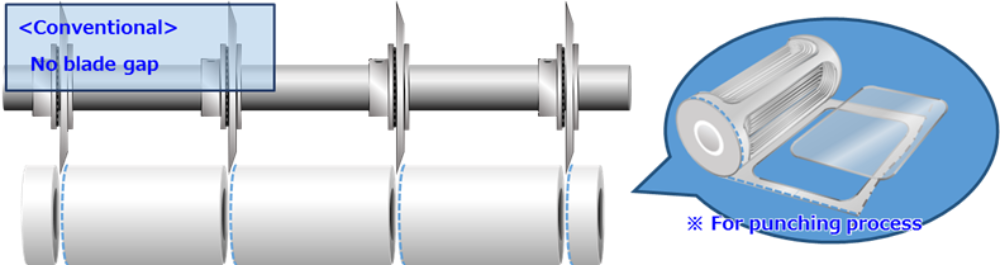

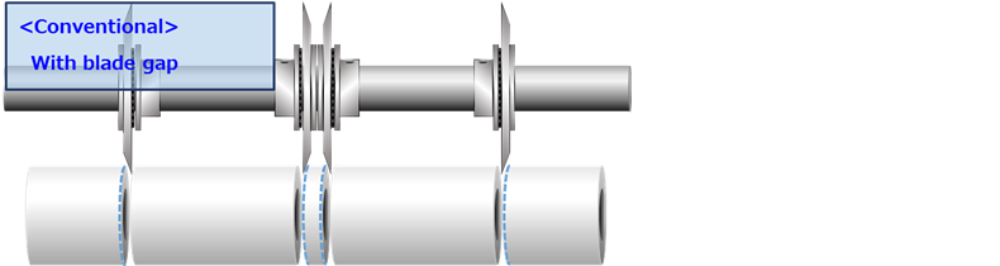

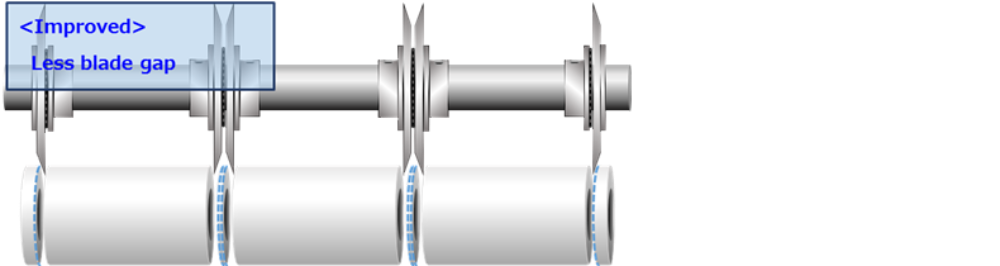

Improving slit loss from 20 mm to 5 mm

20 mm width loss necessary for metal foil slit is improved to 5 mm width loss by using special upper blade holder and the yield is raised.

-

Why slit loss is necessary

Since the slit blade is single-edged, rubbing against the edge of the foil or film may occur when cutting it. When making the slit width product size, it drops in the middle so that the end face of the product will not be damaged.

-

The merit of slit loss

Nomally, if you slit material vertically, the blade will rub against the end face and got scratched. In order to prevent this problem, it is necessary to make some clearances.

However, since the dropping width is determined by the thickness of the holder fixing the blades, much material loss occurs. The yield in the width direction (number of products) will be worse.

Therefore, we solved this problem by preparing a dedicated narrow holder that reduces the thickness of the holder fixing the blade and using it.