Cutting and Lamination cut

- TOP

- Products and service

- Processing and services

- Cutting and Lamination cut

Cutting and

Laminated Cutting

We can cut and process various plastic films, such as optical films, metal foils etc. to the size requested by customers in the clean room. It is also possible to cut from roll to sheet and laminate another material such as protective film on both sides or one side. And we can deliver products with nesessary amount.

We can process film materials into all sorts of shapes and sizes.

Feature FEATURE

-

All processing is done in a clean room.(Class 10000 and Class 1000)

-

We have a production system from large lot to small lot.

-

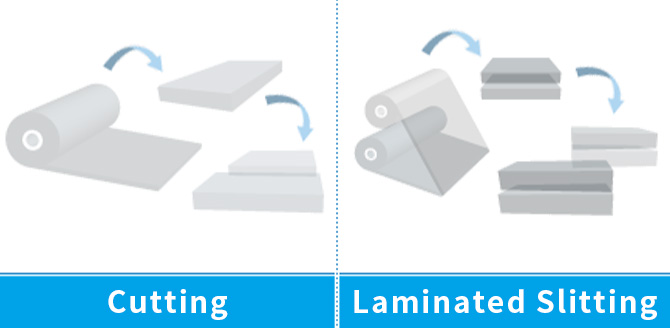

We can laminate up to 3 layers, slit materials and cut materials at the same time.

Idea Idea is here!

-

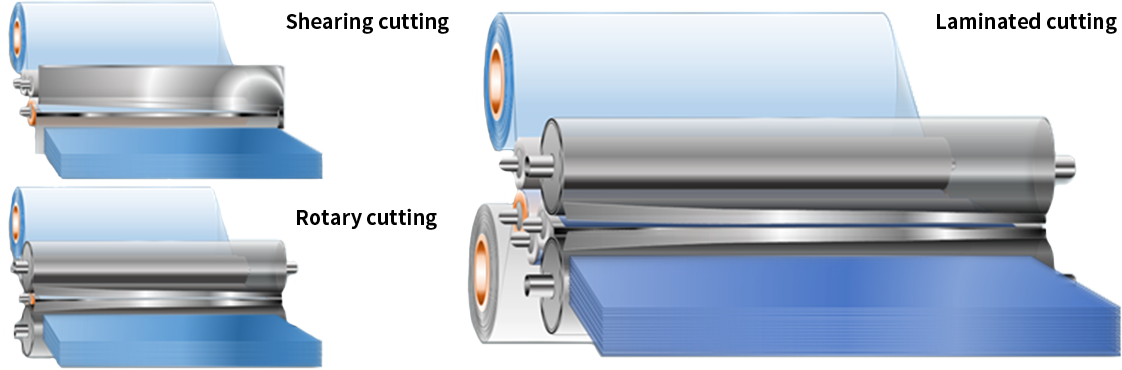

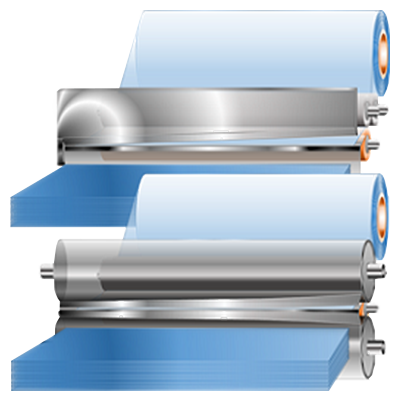

Shearing cutting is a sheet processing method suitable for producing large lot sheets.

-

Rotary cutting is suitable for mass production by using high-speed rotary blades.

-

Other processing methods such as laminated cutting can be combined.

Processing Details PROCESSING DETAILS

Roll to Sheet Cutting machines

| Corresponding size | Material roll width | Material weight | Maximum winding diameter |

|---|---|---|---|

| Input side | ~1300㎜(1700㎜)TD | ~500kg | ~φ600(φ800) |

| Outlet side | ~1300㎜(1700㎜)TD | ~2000㎜ MD | ※Cutting with sensor is available |

| Material thickness | 50~500μm |

| Number of machines | 6 |

Cutting machines

| Corresponding size | Material plate width | Layer weight and the minimum width | Other |

|---|---|---|---|

| Input side | ~1320㎜(MAX) | Until piled 160㎜ | |

| Outlet side | ~1300㎜(MAX) | 80㎜~(MIN) | ※Wide width(2000mm)is available |

| Material thickness | 50~500μm |

| Number of machines | 3 |

※Processing specifications are only guidelines, please contact us for more information.

※Illustrations are only schematic diagrams. They are different from the actual.